Hydraulic symbols are graphical representations used in circuit diagrams, representing components like pumps, valves, and actuators. They follow standards such as ISO 1219, ensuring consistency and clarity. These symbols are crucial for designing, understanding, and troubleshooting hydraulic systems, enabling effective communication among engineers and technicians.

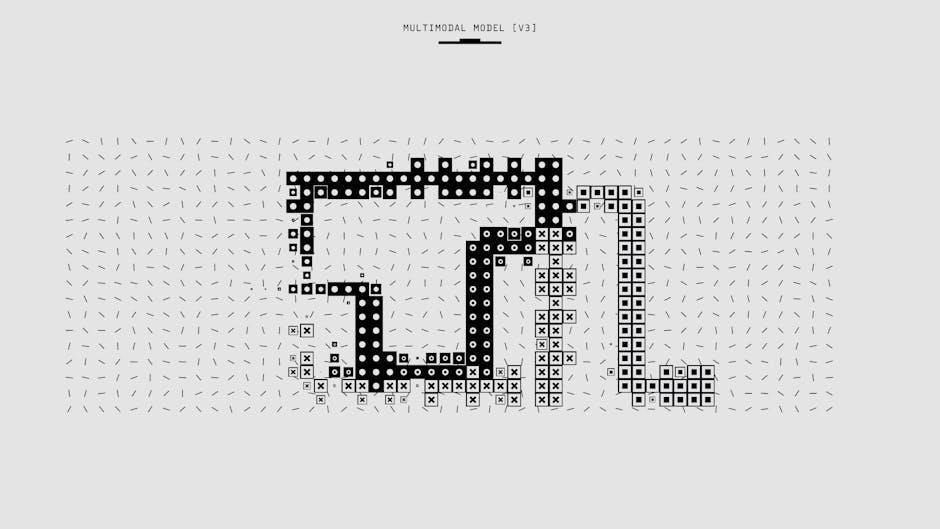

1.1 Definition and Importance of Hydraulic Symbols

Hydraulic symbols are standardized graphical representations of components and functions in hydraulic systems. They are essential for designing, analyzing, and troubleshooting hydraulic circuits. These symbols, often detailed in resources like “hyd symbols pdf,” provide a universal language for engineers and technicians. They simplify complex systems by visually depicting pumps, valves, actuators, and fluid flow directions. The importance lies in their ability to standardize communication, reduce errors, and enhance safety. By following standards such as ISO 1219, hydraulic symbols ensure clarity and consistency across industries. They are indispensable for training, system documentation, and efficient problem-solving in hydraulic applications.

1.2 Brief History of Hydraulic Symbol Development

The development of hydraulic symbols dates back to the early 20th century, evolving alongside hydraulic technology. Initially, symbols were simple and varied by manufacturer, leading to confusion. Standardization efforts emerged in the mid-20th century, with organizations like ISO creating unified systems. The introduction of ISO 1219 in 1976 marked a significant milestone, establishing a global standard for hydraulic and pneumatic symbols. This standardization ensured consistency, improved communication, and enhanced safety across industries. Today, hydraulic symbols, as detailed in resources like “hyd symbols pdf,” are integral to system design, troubleshooting, and education, reflecting a century of refinement and collaboration.

1.3 Standardization of Hydraulic Symbols (ISO 1219)

ISO 1219 is the international standard for hydraulic and pneumatic symbol representation, ensuring uniformity worldwide. It categorizes symbols into basic and composite types, covering components like pumps, valves, and actuators. The standard specifies line types, such as solid for main lines and dotted for pilot lines, and defines flow directions with arrows. ISO 1219 also addresses modular systems and safety components, providing clear guidelines for diagram creation. Resources like “hyd symbols pdf” often reference this standard, making it essential for engineers and technicians to design and interpret hydraulic circuits accurately, ensuring safety and efficiency in system operations across industries.

Basic Hydraulic Components and Their Symbols

Basic hydraulic components include pumps, valves, actuators, and hydraulic lines. Their symbols are standardized for clear representation in circuit diagrams, ensuring consistency and easy understanding.

2;1 Pumps and Motors

Pumps and motors are essential hydraulic components, represented by distinct symbols. Pumps, such as variable displacement types, provide hydraulic power, with output adjusted based on system demand. Motors convert hydraulic energy into mechanical energy, often used in actuators. Their symbols vary, with pumps typically shown as circles or rectangles with internal details indicating displacement control. Motors are often depicted similarly but with arrows showing rotation direction. Load-sensing lines connect pumps to actuators, optimizing energy use by matching output to demand. Proportional control valves regulate flow and direction to these components, ensuring precise operation. These symbols are standardized for clarity in circuit diagrams.

2.2 Valves (Directional, Pressure, Flow Control)

Valves are critical components in hydraulic systems, represented by specific symbols. Directional valves, such as 3-position DCVs, are shown with squares and arrows indicating flow paths. Pressure relief valves are depicted with springs and arrows, regulating system pressure. Flow control valves are represented with symbols showing adjustable restrictions. Pilot lines, often dotted, control valve actuation, while check valves prevent backflow. These symbols are standardized, ensuring clarity in circuit diagrams. They enable precise control of fluid flow, pressure, and direction, essential for system functionality; Understanding these symbols is key to designing and troubleshooting hydraulic systems effectively.

2.3 Actuators (Cylinders, Motors)

Actuators, such as hydraulic cylinders and motors, are represented by distinct symbols in circuit diagrams. Cylinders are typically shown as rectangular boxes with arrows indicating the direction of linear motion. Motors are depicted with circular symbols and arrows showing rotational movement. These symbols are standardized, often following ISO 1219, to ensure clarity. Hydraulic cylinders are commonly used for linear actuation, while motors provide rotational motion. Their symbols are essential for understanding how fluid flow and pressure are converted into mechanical energy. These components are crucial for system functionality, enabling precise control of movement and force in hydraulic applications.

2.4 Hydraulic Lines and Connectors

Hydraulic lines and connectors are represented by specific symbols in circuit diagrams, indicating the flow of hydraulic fluid. Solid lines denote main pressure lines, while dashed lines represent pilot or control lines. Arrows show the direction of fluid flow, and circles or squares may indicate connectors or fittings. Flexible hoses are often shown as wavy lines, while rigid tubes are straight. Connectors are crucial for sealing and directing fluid flow between components. Standardized symbols, such as those in ISO 1219, ensure clarity and consistency in hydraulic system design and troubleshooting. These symbols are essential for understanding fluid transmission paths and system connectivity.

Hydraulic Circuit Diagrams

Hydraulic circuit diagrams use standardized symbols to represent components and their connections, showing fluid flow direction and system operation. Solid lines indicate main pressure, dashed lines pilot control, and wavy lines flexible hoses, with arrows showing flow direction. These diagrams are essential for understanding system functionality and troubleshooting.

3.1 Understanding Hydraulic Circuit Layouts

Hydraulic circuit layouts visually represent system components and their connections using standardized symbols. These diagrams illustrate the flow of hydraulic fluid, pressure lines, and control signals. Arrows indicate fluid direction, while solid lines denote main pressure paths and dashed lines represent pilot or control lines. Each symbol corresponds to a specific component, such as pumps, valves, and actuators, ensuring clarity and consistency. Understanding these layouts is crucial for diagnosing system issues, optimizing performance, and ensuring safe operation. Proper interpretation requires familiarity with ISO 1219 standards and the ability to trace fluid flow through the circuit, identifying key components and their interactions.

3.2 Reading Hydraulic Circuit Diagrams

Reading hydraulic circuit diagrams involves interpreting symbols and lines to understand system functionality. Solid lines represent main fluid paths, while dashed lines indicate control or pilot lines. Arrows show fluid flow direction, and valve positions (NO/N.C.) determine whether flow is allowed or blocked. Each component, like pumps or actuators, is depicted by specific symbols. Color coding may highlight pressure levels or fluid types. By tracing the flow from the pump through valves to actuators and back to the reservoir, one can identify system operation, control logic, and energy efficiency. Familiarity with ISO 1219 standards ensures accurate interpretation, enabling effective troubleshooting and system optimization.

3.3 Common Symbols Used in Circuit Diagrams

Common hydraulic symbols include representations of pumps, valves, actuators, and lines. Pumps are often shown as circles with internal details, while valves are depicted as squares with arrows indicating flow paths. Actuators like cylinders are illustrated with rectangular blocks and arrows showing movement direction. Lines are differentiated: solid for main fluid paths, dashed for pilot or control lines, and dotted for drain or exhaust lines. Arrows indicate fluid flow direction, and valve positions (NO/N.C.) show normal operation states. These symbols, standardized in ISO 1219, provide a universal language for understanding hydraulic circuits, enabling clear communication and efficient system design and troubleshooting.

Hydraulic Fluid Flow and Directional Symbols

Arrows indicate fluid flow direction, while pilot lines (dotted) and drain lines (dotted with tank endings) show control and exhaust paths, essential for circuit functionality and safety.

4.1 Arrows and Flow Direction

Arrows in hydraulic symbols indicate the direction of fluid flow, essential for understanding circuit operation. Solid lines represent main fluid paths, while dashed lines denote pilot or control flows. The arrow’s position on a valve symbol shows its normal state, such as normally open (NO) or normally closed (NC). Arrows also specify actuator movement direction, like linear or rotational motion. Pilot lines, often dotted, control valve actions, while drain lines, ending in tanks, manage excess fluid. These directional indicators align with ISO 1219 standards, ensuring clarity and consistency in hydraulic system design and troubleshooting, making them indispensable for engineers and technicians alike.

4.2 Pilot Lines and Control Signals

Pilot lines and control signals are crucial in hydraulic systems for managing valve operations and system responses. These lines, often represented by dashed or dotted lines, carry low-pressure fluid to control valves, enabling precise regulation of flow and pressure. Control signals can be mechanical, electrical, or hydraulic, ensuring valves function as intended. Pilot-operated valves use these lines to sense system pressure and adjust accordingly, maintaining stability and efficiency. The integration of pilot lines with proportional valves allows for advanced control, such as load-sensing systems, where the pump adjusts output based on demand. This ensures energy efficiency and optimal performance across various hydraulic applications, from industrial machinery to mobile equipment.

4.3 Drain and Exhaust Lines

Drain and exhaust lines are essential for safely returning hydraulic fluid to the reservoir and venting excess pressure. These lines are typically represented by dotted or dashed lines in circuit diagrams, often terminating in a tank or reservoir symbol. Their primary function is to prevent fluid overflow and ensure system stability by providing a controlled path for excess fluid to exit. Exhaust lines also play a role in releasing pressurized fluid from components like valves and cylinders, preventing damage from over-pressurization. Properly designed drain and exhaust lines are critical for maintaining hydraulic system efficiency, safety, and longevity, ensuring reliable operation across various applications.

Pressure and Control Symbols

Pressure and control symbols represent components managing hydraulic system pressure and fluid flow. These include pressure relief valves, proportional control valves, and load-sensing lines, ensuring precise system regulation and safety.

5.1 Pressure Relief Valves

Pressure relief valves are essential components in hydraulic systems, protecting against excessive pressure buildup. Their symbols typically feature a spring and arrow, indicating pressure regulation. These valves vent excess fluid when pressure exceeds safe levels, preventing system damage. They are often located near proportional control sections and act as safety mechanisms. The valve opens to redirect fluid to the tank when pressure surpasses the set limit, ensuring system stability. This function is critical in maintaining operational safety and preventing component failure. Pressure relief valves are fundamental in hydraulic circuits, especially those with fixed displacement pumps, where excess flow must be safely diverted.

5.2 Proportional Control Valves

Proportional control valves are advanced components that regulate fluid flow and pressure in hydraulic systems. Their symbols often include ports labeled A and B, representing inlet and outlet paths; These valves use pilot pressure to control the flow direction and magnitude, enabling precise actuator movement. They are commonly used in modular systems, allowing flexibility in system design. Proportional valves ensure efficient energy use by adjusting output based on demand, working in conjunction with load-sensing lines. Their ability to provide variable control makes them essential for applications requiring high accuracy and smooth operation. They are a key component in modern hydraulic systems, enhancing performance and efficiency.

5.3 Load-Sensing Lines and Systems

Load-sensing lines and systems are critical for optimizing hydraulic system performance. These lines connect actuators to the pump, enabling real-time pressure feedback. The load-sensing line adjusts the pump’s displacement based on demand, ensuring energy efficiency by only producing the required flow. This system is essential for maintaining precise control and reducing energy waste. The LS shuttle valve arrangement compares pressures from multiple sections, ensuring the pump supplies adequate flow to the most demanding actuator. This setup allows for smooth, efficient operation, making it ideal for complex hydraulic applications requiring dynamic control and energy savings. Load-sensing systems enhance overall system responsiveness and efficiency.

Hydraulic System Components and Their Symbols

Hydraulic systems rely on components like pumps, motors, cylinders, and valves, each represented by specific symbols. These symbols are standardized in diagrams to depict functionality and design clearly.

6.1 Hydraulic Cylinders and Motors

Hydraulic cylinders and motors are essential components, converting hydraulic energy into mechanical motion. Cylinders are represented by rectangular symbols with arrows indicating piston movement direction. Motors are shown as circular or oval symbols with arrows denoting rotation. Both symbols include ports for fluid entry and exit, with lines indicating flow direction. These components are crucial for actuation and power transmission in hydraulic systems. Their symbols are standardized, ensuring clarity in circuit diagrams. Proper representation aids in understanding system functionality and troubleshooting. Each symbol’s detail, like port configurations, helps engineers design and analyze hydraulic circuits effectively.

6.2 Hydraulic Pumps (Fixed and Variable Displacement)

Hydraulic pumps are the heart of hydraulic systems, providing the necessary flow and pressure. Fixed displacement pumps maintain a constant flow rate, represented by a square symbol with a solid line indicating flow direction. Variable displacement pumps adjust their output, shown by a similar square with additional lines or arrows indicating adjustability. Both types are essential for system operation, with variable pumps offering energy efficiency by matching output to demand. Their symbols in circuit diagrams are standardized, ensuring clear communication of pump functionality. Proper representation aids in system design and troubleshooting, highlighting the pump’s role in energy transmission within hydraulic circuits.

6.3 Hydraulic Filters and Coolers

Hydraulic filters and coolers are essential for maintaining system efficiency and longevity. Filters, represented by a grid-like symbol, remove contaminants from the hydraulic fluid, ensuring clean flow to components. They are often placed upstream of pumps and valves to protect them from debris. Coolers, shown as a series of lines or coils, dissipate heat generated by system operation, preventing fluid degradation and component damage. Both components are critical for reliable performance, with their symbols standardized in diagrams for clear identification. Proper placement and sizing of filters and coolers are vital for optimal system operation and extended equipment life.

Composite and Modular Hydraulic Symbols

Composite and modular symbols simplify complex systems by combining multiple components into a single representation. They are used in circuit diagrams to enhance clarity and ease of design.

7.1 Modular Valve Systems

Modular valve systems combine multiple hydraulic components into a single, compact unit, simplifying installation and maintenance. These systems often include proportional control valves, pressure relief valves, and check valves. They are designed to handle complex fluid flow requirements efficiently. Modular systems allow for easy addition or removal of sections based on system needs, enhancing flexibility. Each section typically controls an actuator independently, ensuring precise operation. Load-sensing lines and pilot pressure lines are integral to these systems, enabling energy-efficient performance by adjusting flow based on demand. Standardized symbols, such as those in ISO 1219, are used to represent these components in circuit diagrams, ensuring clarity and consistency.

7.2 Composite Symbols for Complex Components

Composite symbols represent complex hydraulic components by combining multiple basic symbols into a single, unified representation. These symbols are used for components like modular valve systems, which integrate several functions such as proportional control, pressure relief, and flow regulation. Composite symbols simplify circuit diagrams by reducing visual clutter and improving readability. They are particularly useful for illustrating how multiple components interact within a single unit. Standards like ISO 1219 provide guidelines for creating these symbols, ensuring consistency and ease of interpretation. By using composite symbols, engineers can more effectively communicate the design and operation of intricate hydraulic systems, making diagrams easier to understand and work with.

7.3 Modular Circuit Diagrams

Modular circuit diagrams are detailed visual representations of hydraulic systems, focusing on the interaction between components within a modular framework. These diagrams use composite symbols to depict complex components, such as proportional valves and load-sensing systems, in a simplified manner. They illustrate how modules like pumps, valves, and actuators are interconnected, highlighting flow paths, control signals, and energy distribution; Modular diagrams are essential for understanding system operation, troubleshooting, and design. They often include standardized symbols from ISO 1219, ensuring clarity and consistency. By breaking down systems into modules, engineers can easily identify and modify specific sections, enhancing scalability and maintainability.

Hydraulic System Safety Symbols

Safety symbols in hydraulic systems indicate critical components like pressure relief valves, check valves, and safety control lines. They ensure safe operation by preventing over-pressurization and fluid backflow, protecting both equipment and personnel from potential hazards.

8.1 Pressure Relief Valves

Pressure relief valves are essential safety components in hydraulic systems, designed to protect against over-pressurization. These valves vent excess pressure when it exceeds a set limit, preventing system damage. They are often located near proportional control valves and act as a safeguard by releasing fluid to the tank or reservoir. Proper functioning ensures equipment longevity and operator safety. Their operation is typically spring-loaded, with adjustable settings to match system requirements. Failure to install or maintain these valves can lead to catastrophic failures, making them a critical element in hydraulic circuit design and operation. They are universally recognized in hydraulic symbol standards like ISO 1219.

8.2 Check Valves

Check valves are one-way valves that allow fluid to flow in one direction while preventing backflow in the opposite direction. They are essential for maintaining pressure in specific parts of a hydraulic circuit and ensuring proper fluid flow direction. These valves are often spring-loaded or pilot-operated, with the spring providing the closing force. In hydraulic symbols, check valves are typically represented by an arrow indicating the allowed flow direction, combined with a blocking symbol for the reverse flow. They are critical for system safety, preventing damage from backflow and ensuring consistent operation. Their proper functioning is vital for maintaining hydraulic system efficiency and reliability.

8.3 Safety Control Lines

Safety control lines are essential components in hydraulic systems, ensuring safe operation by monitoring and regulating critical functions. These lines are often represented in hydraulic diagrams as dotted lines, indicating their role in control and monitoring rather than fluid flow. They connect components like pressure relief valves and proportional control valves, enabling precise control and emergency shutdowns when necessary. Safety control lines are crucial for preventing system overpressure and ensuring compliance with safety standards. They work in conjunction with other safety mechanisms, such as check valves, to maintain system integrity and protect against potential hazards. Their proper implementation is vital for reliable and safe hydraulic system performance.

Hydraulic System Applications

Hydraulic systems are widely used in industrial machinery, mobile equipment, and aerospace applications. They provide precise control and high power density, making them essential for heavy-duty operations and automation.

9.1 Industrial Machinery

Hydraulic symbols are essential in industrial machinery for representing components like pumps, valves, and cylinders. These symbols, standardized in documents like ISO 1219, enable clear communication among engineers. They simplify the design and troubleshooting of hydraulic systems used in manufacturing, material handling, and heavy machinery. By standardizing symbols, industries ensure consistency, reducing errors and enhancing efficiency. Hydraulic systems in industrial machinery rely on these symbols to depict flow direction, pressure control, and component interactions. This standardized visualization aids in training technicians and ensures safe, reliable operation of complex hydraulic systems across various industrial applications.

9.2 Mobile Hydraulics

Mobile hydraulics integrates hydraulic systems into vehicles and equipment like excavators, cranes, and wheel loaders. Hydraulic symbols are crucial for designing and troubleshooting these systems, ensuring efficient operation. Symbols for pumps, motors, and directional control valves are commonly used, representing flow paths and system logic. These symbols help technicians understand fluid flow, pressure regulation, and energy transmission in mobile applications. Standardized symbols, as per ISO 1219, enhance clarity and consistency, reducing errors. Mobile hydraulic systems rely on these visual representations to optimize performance, maintain safety, and enable precise control of heavy machinery in dynamic environments, making them indispensable in construction and agriculture industries.

9.3 Aerospace Hydraulics

In aerospace, hydraulic systems are critical for controlling aircraft mechanisms like landing gear, flaps, and thrust vectoring. Hydraulic symbols are essential for designing and maintaining these systems, ensuring precise control and reliability. Symbols for pumps, actuators, and proportional control valves are widely used, representing complex flow paths and pressure regulation. ISO 1219 standards guide the representation of these components, enabling clear communication among engineers. Aerospace hydraulics requires lightweight, high-performance systems, and symbols play a key role in optimizing design and troubleshooting. They help visualize fluid flow, pressure, and directional control, ensuring safety and efficiency in demanding aviation environments.

Educational Resources for Hydraulic Symbols

PDF guides, online courses, and software tools provide comprehensive learning on hydraulic symbols. These resources offer detailed explanations, diagrams, and practical examples, following standards like ISO 1219 for clarity and accuracy.

10.1 PDF Guides and Manuals

PDF guides and manuals are essential resources for understanding hydraulic symbols. They provide detailed explanations of basic and composite symbols, along with examples of circuit diagrams. These documents often follow international standards like ISO 1219, ensuring accuracy and consistency. Many PDFs include sections on pumps, valves, actuators, and fluid lines, making them comprehensive tools for engineers and students. They also offer practical examples and troubleshooting tips, enhancing learning and application. These guides are widely available online, making them accessible for educational and professional use in hydraulic system design and maintenance.

10.2 Online Courses and Tutorials

Online courses and tutorials offer interactive learning experiences for mastering hydraulic symbols. Platforms like Udemy and Coursera provide structured lessons, covering basic to advanced topics. These courses often include video tutorials, quizzes, and practical exercises to enhance understanding. Many focus on ISO 1219 standards, ensuring learners grasp industry-recognized symbols. Tutorials also cover circuit diagram interpretation, component identification, and system design. They cater to both beginners and professionals, offering flexible learning opportunities. Additionally, specialized websites and YouTube channels provide free tutorials, making hydraulic symbol education accessible to everyone. These resources are invaluable for engineers, technicians, and students seeking to improve their hydraulic system design and troubleshooting skills.

10.3 Hydraulic Symbol Software Tools

Hydraulic symbol software tools streamline the creation and editing of circuit diagrams. Programs like AutoCAD, SolidWorks, and specialized hydraulic design software offer libraries of ISO 1219-compliant symbols. These tools enable users to drag-and-drop components, connect lines, and customize diagrams efficiently. Some software includes simulation features to test system performance. They are essential for engineers and designers, ensuring accuracy and compliance with industry standards. Additionally, free and open-source options like Fritzing provide affordable solutions for educational and small-scale projects. These tools enhance productivity and precision, making them indispensable for modern hydraulic system design and documentation.

Hydraulic symbols are essential for designing, analyzing, and troubleshooting hydraulic systems. They provide a universal language, ensuring clarity and efficiency in communication among engineers and technicians. By following standards like ISO 1219, these symbols maintain consistency across industries. The availability of resources such as PDF guides, online courses, and specialized software tools further enhances the understanding and application of hydraulic symbols. As technology advances, these tools continue to evolve, offering improved functionality and accuracy. Mastery of hydraulic symbols is crucial for anyone working with fluid power systems, enabling safer and more efficient hydraulic system design and operation.