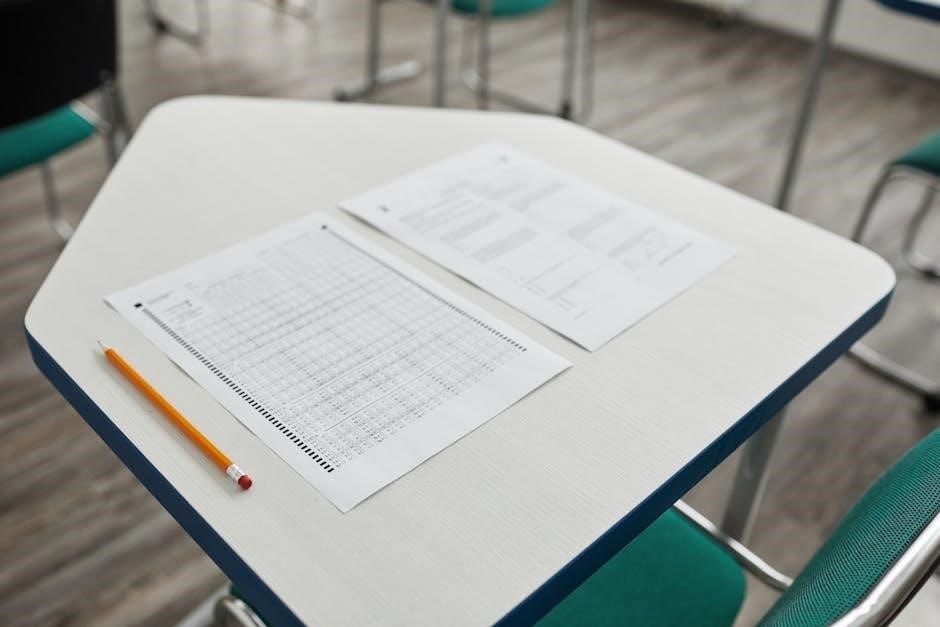

Maintenance test questions and answers PDFs are essential resources for individuals preparing for industrial maintenance exams or seeking to enhance their technical skills. These documents provide a comprehensive collection of questions and answers tailored to assess knowledge in areas such as electrical systems, hydraulics, pneumatics, and programmable logic controllers (PLCs). Designed for both students and professionals, these PDFs serve as valuable study guides for certification exams, pre-hire assessments, and self-study programs.

- They cover a wide range of topics, including preventive maintenance strategies, equipment diagnostics, and safety protocols.

- Questions are often multiple-choice or scenario-based, challenging the user to apply practical knowledge to real-world problems.

- Answers are provided with detailed explanations, helping learners understand core concepts and improve problem-solving abilities.

By utilizing these resources, maintenance technicians can identify knowledge gaps, refine their skills, and stay updated with industry standards. Whether for exam preparation or professional development, maintenance test questions and answers PDFs are indispensable tools for achieving success in the field.

Importance of Maintenance Test Questions

Maintenance test questions play a pivotal role in ensuring the competency, safety, and efficiency of maintenance operations across various industries. These assessments are designed to evaluate an individual’s knowledge, skills, and problem-solving abilities in maintaining and repairing equipment, machinery, and facilities. The importance of maintenance test questions extends beyond mere evaluation; they serve as a critical tool for enhancing professional development, ensuring workplace safety, and optimizing operational efficiency. Below are some key reasons why maintenance test questions are essential in the field of industrial maintenance.

Evaluation of Technical Competency

One of the primary purposes of maintenance test questions is to assess the technical competency of maintenance technicians. These questions cover a wide range of topics, including electrical systems, hydraulics, pneumatics, programmable logic controllers (PLCs), and mechanical systems. By evaluating a technician’s understanding of these areas, employers and educational institutions can determine whether an individual possesses the necessary skills to perform maintenance tasks effectively. This ensures that only qualified professionals are entrusted with critical maintenance responsibilities, reducing the risk of errors and equipment damage.

Enhancement of Problem-Solving Skills

Maintenance work often involves diagnosing and resolving complex issues with machinery and equipment. Maintenance test questions are designed to simulate real-world scenarios, challenging technicians to apply their knowledge and experience to troubleshoot problems. For example, a question might ask how to identify the cause of a hydraulic system failure or how to repair a faulty electrical circuit. By practicing these types of questions, technicians can refine their problem-solving skills, enabling them to address maintenance challenges more efficiently in the workplace.

Improvement of Workplace Safety

Safety is a paramount concern in industrial maintenance, as technicians often work with hazardous equipment and systems. Maintenance test questions frequently include scenarios related to safety protocols, such as lockout/tagout procedures, the use of personal protective equipment (PPE), and emergency response strategies. By assessing a technician’s knowledge of safety practices, these tests help ensure that individuals are prepared to work safely and responsibly. This not only protects the technician but also prevents accidents that could harm others or damage equipment.

Preparation for Certification Exams

Certifications are highly valued in the maintenance field, as they demonstrate a technician’s expertise and commitment to professional development. Maintenance test questions are often modeled after certification exam formats, providing individuals with a realistic preview of the types of questions they may encounter. For instance, questions related to PLC programming, motor control circuits, or pneumatic systems can help technicians prepare for certifications like the Certified Maintenance Technician (CMT) or the Industrial Maintenance Technician (IMT) exams. Regular practice with these questions enhances exam readiness and increases the likelihood of success.

Identification of Knowledge Gaps

Maintenance test questions are an effective tool for identifying areas where additional training or study may be needed. When technicians encounter questions they struggle with, it highlights gaps in their knowledge or experience. This allows them to focus their learning efforts on specific topics, such as advanced hydraulic systems or predictive maintenance techniques. Employers can also use these assessments to identify training needs within their teams, ensuring that all technicians are up-to-date with industry standards and best practices.

Support for Preventive Maintenance Practices

Preventive maintenance is a cornerstone of industrial maintenance, as it helps prevent equipment failures and reduces downtime. Maintenance test questions often address strategies and techniques for implementing preventive maintenance programs. For example, questions may cover routine inspection schedules, lubrication practices, or condition monitoring methods. By reinforcing these concepts, the tests encourage technicians to adopt a proactive approach to maintenance, which can lead to significant cost savings and improved operational efficiency for organizations.

Adaptation to Emerging Technologies

The field of industrial maintenance is constantly evolving, with advancements in technologies such as predictive maintenance, the Internet of Things (IoT), and automation. Maintenance test questions reflect these changes by incorporating topics related to new tools and methodologies. For instance, questions may focus on interpreting data from IoT sensors or troubleshooting issues with automated systems. By staying current with these developments, technicians can adapt to the demands of modern maintenance environments and remain competitive in their careers.

Standardization of Maintenance Practices

Maintenance test questions help standardize maintenance practices by ensuring that technicians adhere to established industry standards and best practices. For example, questions may reference specific codes or regulations, such as NFPA 70E for electrical safety or OSHA guidelines for workplace safety. This standardization promotes consistency in maintenance procedures, reducing variability and improving overall quality. It also ensures that technicians are familiar with the same set of principles and protocols, facilitating collaboration and communication within teams.

Cost Savings Through Efficient Maintenance

Efficient maintenance practices are essential for minimizing operational costs and maximizing equipment lifespan. Maintenance test questions emphasize the importance of cost-effective strategies, such as reducing energy consumption, optimizing resource usage, and extending the service life of equipment. By evaluating a technician’s ability to implement these strategies, the tests contribute to more efficient maintenance operations, which can lead to significant financial savings for organizations.

In summary, maintenance test questions are indispensable for evaluating and enhancing the skills of maintenance technicians. They play a crucial role in ensuring technical competency, improving problem-solving abilities, promoting workplace safety, and preparing individuals for certification exams. Additionally, these questions help identify knowledge gaps, support preventive maintenance practices, and adapt to emerging technologies. By leveraging these resources, technicians can achieve professional growth, and organizations can benefit from more efficient, safe, and cost-effective maintenance operations.

Key Topics Covered in Maintenance Tests

Maintenance tests are designed to assess a technician’s knowledge and skills across a wide range of technical areas critical to the field of industrial maintenance. These tests typically cover key topics that are essential for performing maintenance tasks safely, efficiently, and effectively. Below is an overview of the primary subjects and areas of focus that are commonly included in maintenance tests.

Electrical Systems and Circuits

Understanding electrical systems is fundamental for any maintenance technician. Maintenance tests often include questions on the basics of electricity, including Ohm’s Law, voltage, current, and resistance. Technicians are also expected to interpret circuit diagrams, identify components such as resistors, capacitors, and inductors, and troubleshoot electrical issues. Knowledge of motor control circuits, including starters and contactors, is also frequently tested. Additionally, questions may cover the proper use of multimeters for measuring electrical properties and the application of safety protocols when working with live electrical systems.

Hydraulics and Pneumatics

Hydraulic and pneumatic systems are integral to many industrial applications, and maintenance tests often include questions on these topics. Technicians are expected to understand the principles of fluid pressure, flow rates, and the operation of pumps, valves, and actuators. Differences between hydraulic and pneumatic systems, such as the use of incompressible fluids in hydraulics and compressed air or gas in pneumatics, are also covered. Common maintenance tasks, such as inspecting hydraulic hoses, checking fluid levels, and troubleshooting leaks, are frequently addressed in test questions. Safety practices, such as relieving pressure before servicing, are also emphasized.

Programmable Logic Controllers (PLCs)

PLCs are a cornerstone of modern industrial automation, and their operation and programming are key topics in maintenance tests. Technicians are expected to understand how PLCs receive input signals, execute programmed logic, and generate output signals to control machinery. Common tasks covered in tests include interpreting ladder logic diagrams, configuring I/O modules, and performing routine diagnostics. Questions may also focus on programming languages, communication protocols, and fault detection. Mastery of PLC systems is essential for maintaining and optimizing industrial processes, making this a critical area of focus in maintenance exams.

Mechanical Systems and Components

Mechanical systems, including bearings, gears, and power transmission components, are frequently tested in maintenance exams. Technicians must demonstrate an understanding of how these components function and how to perform routine maintenance tasks, such as lubrication and inspection. Questions may also cover the identification and replacement of worn or damaged parts, as well as the alignment of machinery. Knowledge of mechanical safety practices, such as proper tool usage and lockout/tagout procedures, is also essential.

Predictive and Preventive Maintenance

Predictive and preventive maintenance strategies are critical for minimizing downtime and extending the lifespan of equipment. Maintenance tests often include questions on the implementation of these strategies, including routine inspections, condition monitoring, and scheduled servicing. Technicians are expected to understand how to identify potential issues before they lead to equipment failure, as well as how to analyze data from sensors and other monitoring tools. Questions may also cover the development of maintenance schedules and the use of tools like vibration analysis and thermal imaging.

Safety Protocols and Practices

Safety is a paramount concern in industrial maintenance, and tests often include questions on safety protocols and practices. Technicians must demonstrate knowledge of personal protective equipment (PPE), lockout/tagout procedures, and emergency response strategies. Questions may also cover industry-specific safety standards, such as NFPA 70E for electrical safety and OSHA guidelines for workplace safety. Understanding how to interpret safety data sheets (SDS) and handle hazardous materials is also frequently tested.

Industrial Safety and Compliance

Maintenance tests often include questions on industrial safety and compliance with regulatory standards. Technicians are expected to understand how to conduct risk assessments, implement safety audits, and ensure compliance with industry regulations. Questions may also cover the proper use of safety equipment, such as fire extinguishers and fall protection gear, and the procedures for reporting incidents and near-misses. Knowledge of environmental regulations and waste management practices may also be included.

Tool Usage and Equipment Diagnostics

The proper use of tools and equipment is essential for performing maintenance tasks effectively; Maintenance tests often include questions on the use of hand tools, power tools, and specialized equipment, such as multimeters and hydraulic pressure testers. Technicians are also expected to demonstrate the ability to diagnose and repair equipment using these tools. Questions may cover the calibration of tools, the interpretation of diagnostic data, and the troubleshooting of common equipment issues.

Industrial Automation and Control Systems

Industrial automation and control systems are increasingly complex, and maintenance tests often include questions on the operation and maintenance of these systems. Technicians are expected to understand how to program and troubleshoot automation systems, including PLCs, SCADA systems, and human-machine interfaces (HMIs). Questions may also cover the integration of sensors, actuators, and other devices into automated systems, as well as the use of industrial communication protocols like Modbus and Ethernet/IP.

Emergency Response and Troubleshooting

Maintenance tests often include questions on emergency response procedures and troubleshooting techniques. Technicians must demonstrate the ability to respond to equipment failures, electrical emergencies, and other critical situations. Questions may cover the steps for isolating faulty systems, identifying the root cause of problems, and implementing temporary or permanent repairs. Knowledge of emergency response plans and the use of emergency shutdown systems is also frequently tested.

Industry-Specific Maintenance Practices

Maintenance tests may also include questions tailored to specific industries, such as manufacturing, healthcare, or facilities management. For example, technicians in the food processing industry may be tested on sanitation and hygiene practices, while those in the healthcare sector may face questions on medical equipment maintenance. Understanding industry-specific regulations, standards, and best practices is essential for success in these exams.

Sustainable Maintenance Practices

As industries increasingly focus on sustainability, maintenance tests may include questions on environmentally friendly maintenance practices. Technicians are expected to understand how to reduce energy consumption, minimize waste, and extend the lifespan of equipment. Questions may cover the use of energy-efficient technologies, the recycling of materials, and the implementation of green maintenance strategies.